Description

The KGY ECO250 Heater Introduction:

The KGY ECO-250 industrial Heater is designed to provide heating, fresh air, and air recirculation for greenhouses, factories, workshops, and large spaces. Its cylindrical structure features a solid build with a quick assembly chassis system. The axial fan efficiently moves a large volume of air, offering flexibility for both channel and non-channel connections.

The KGY ECO-250 boasts a high level of safety, efficiency, and durability, resulting in cost savings for operations.

The KGY ECO250 Heater Structure:

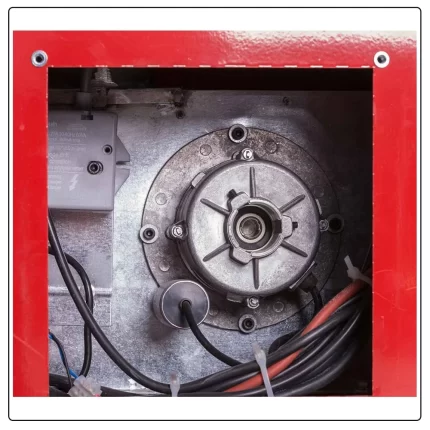

The KGY ECO-250 Industrial Heater comprises a robust body housing a 3 kW (4 HP) motor. A fireproof polymer fan with a capacity of 1400 rpm and a combustion chamber with a heat exchanger contribute to its effective functioning. The axial fan’s design promotes a high-speed flow of hot air, crucial for large spaces.

The intake of air from the top facilitates the recirculation of hot air from the greenhouse’s height, leading to significant fuel consumption reduction. The design ensures easy access to burner equipment and electrical panels. The inclusion of a Burner Control Unit (BCU) simplifies operation.

The KGY ECO250 Heater Performance:

The KGY ECO-250 operates as a gas or diesel-fueled hot air furnace, ensuring a straightforward installation process by connecting electricity, gas or diesel, and the flue. Its adaptability to customer heating needs is a noteworthy feature. The aerodynamic technology facilitates efficient circulation, enhancing energy savings.

Installation options include vertical placement on the floor, with or without a base. The ECO-250 excels in quick and uniform hot air distribution, presenting an economical heating solution for greenhouses, factories, and large halls.

The KGY ECO250 Heater Features:

The ECO-250’s body is constructed from hot-galvanized material, covered with electrostatic powder paint for protection and optical resistance. The steel boiler and multi-layered heat exchanger contribute to its superior heating capabilities. Pressed and detachable connections allow for quick part replacement.

The industrial heater incorporates a 9-blade polyamide axial fan with high ventilation (50,000 cubic meters per hour).

The KGY ECO250 Heater Design:

The KGY ECO-250’s special design ensures uniform heating in minimal time while occupying minimal space in the hall (1.2 square meters). Its aerodynamic furnace and body design maximize efficiency, achieving levels above 92%. Additionally, it facilitates cost-effective transportation in large quantities.

The KGY ECO250 Heater Control:

Equipped with a mechanical control system, the electrical panel ensures high safety. Control options include temperature sensors, a thermostat for the fan and burner with manual adjustment, and a clock programming system. A winter/summer key is included for airflow regulation, and the heater can be turned off via the control panel.

The KGY ECO250 Heater Furnace Analog Thermostat:

An analog furnace thermostat prevents the KGY ECO-250 from operating uncontrollably, regulating the burner based on the furnace temperature.

The KGY ECO250 Heater Fan Analog Thermostat:

Controlled by the furnace temperature, the fan operates to maintain a comfortable temperature range for the outgoing air.

The KGY ECO250 Heater Phase Load Control:

This greenhouse heater utilizes phase-load control to manage voltage levels, phase order, protect the electric motor, and prevent thermal current and electrical overload mixing.

The KGY ECO250 Heater Miniature Fuse:

Suitable miniature fuses safeguard the KGY ECO-250 from electric short circuits and current increases.

The KGY ECO250 Heater Manual Fan Selection Key:

The Zero and One keys enable independent fan activation for ventilation without heating.

The KGY ECO250 Heater Automatic Selection Key:

This key activates automatic mode, starting the burner and fan automatically.

The KGY ECO250 Heater Contactor 25A:

Controlling various loads, including electric motors and circuits, the 25A contactor enhances operational control.

The KGY ECO250 Heater LED Signal Lights:

Indicator lamps confirm the presence of three-phase electricity in the electrical panel.

Reviews

There are no reviews yet.