Description

The KGY Jet Heater Introduction:

The KGY Jet Heater Series is meticulously designed with a primary focus on safety, ease of repair, and optimal performance. A dedicated enclosure houses all electrical and fuel systems, ensuring stringent safety standards and facilitating seamless part replacement. The design also prevents airflow path obstructions, contributing to complete combustion and efficient air circulation. This results in balanced carbon dioxide levels and uniform heat distribution, distinguishing the KGY jet heater. Noteworthy reasons for choosing the KGY jet heater include its superior quality, reasonable pricing, and the promotion of complete fuel combustion, enhancing overall performance.

The KGY Jet Heater Performance:

KGY introduces the 55 and 60 models, featuring direct flame jet heaters with advanced control and flame formation systems. The addition of an efficient safety system sets these heaters apart from older models. Their versatility with both gas and gasoil, coupled with nearly 100% efficiency, makes them popular choices for applications in greenhouses and poultry farms.

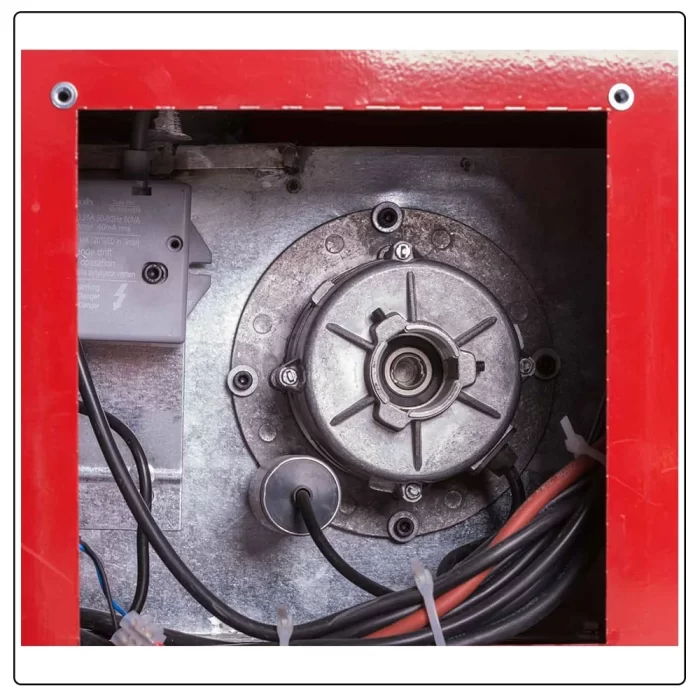

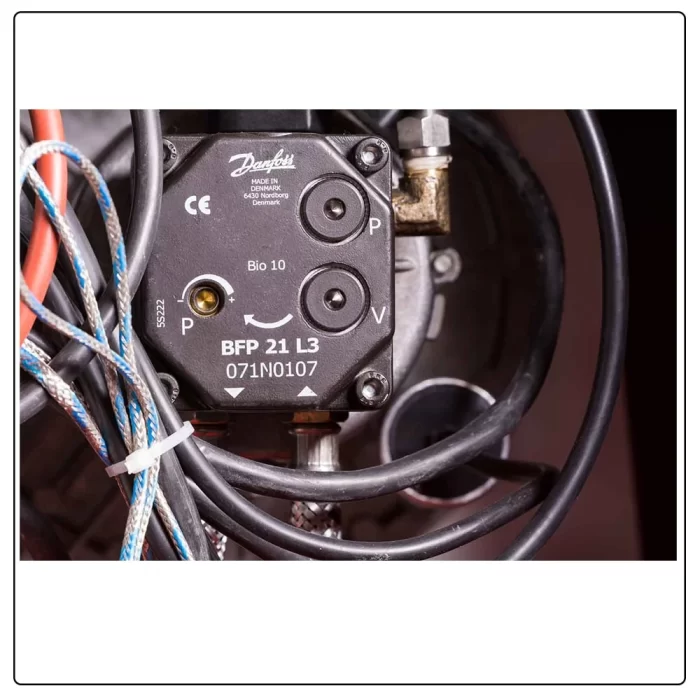

The KGY Jet Heater Structure:

The body of the KGY jet heater is crafted from hot galvanized material with electrostatic powder paint for optimal resistance. Equipped with a DANFOSS gasoil pump from Denmark and a DUNGS gas gradual valve from Germany, all burner and control system accessories are conveniently housed in a box for easy access. The KGY jet heater’s combustion chamber, crucial for complete combustion, is constructed from stainless steel. A dual motor ensures sufficient oxygen supply, and emergency features like an emergency thermo-switch add an extra layer of safety.

The KGY Jet Heater Control:

The electrical and mechanical panel of the KGY jet heater is equipped with multiple control sensors, ensuring correct and safe operation. Integration with automation, environmental thermostat, and other industrial controllers allows for fully automatic operation of the KGY jet heater. Photocell and ion sensors are incorporated for flame control, while a polymer waterproof control panel enhances durability in the KGY jet heater.

Gasoil Pump:

The gasoil pump of the KGY jet heater facilitates the transfer of gasoil to the injector, maintaining essential pressure behind the nozzles. Driven directly by the burner electromotor, it plays a crucial role in the combustion process.

Mode Selection Switch:

In the KGY jet heater for ventilation without heating, the zero and one keys start the fan independently, providing flexibility in usage.

Gasoil Filter:

To prevent impurities from entering the burner pump and causing nozzle blockages, gasoil filters are installed in the KGY jet heater.

Handle:

Special foldable handles are designed for convenient and safe movement of the KGY jet heater.

Air Pressure Controller:

This component in the KGY jet heater ensures the correct operation of the burner fan. If the incoming air falls below the required level, it automatically cuts off the gas or gasoil flow, preventing gas accumulation and potential hazards.

Central Digital Controller:

The central digital unit in the KGY jet heater is responsible for controlling the burner, main fan, and issuing all control and safety commands. The central digital controller boasts high accuracy, long service life, and ease of installation and replacement.

12 A Contactor:

Used for controlling various charges of the KGY jet heater, including electromotors and circuits, the contactor adds to the overall control functionality.

Burner Relay:

The Burning Control Unit (BCU) oversees the combustion process, automatically turning off the flame in case of issues and providing error messages.

Microswitch:

This component controls the operation of the KGY jet heater fan. When off, it prevents the burner from activating, avoiding potential fire hazards.

Reviews

There are no reviews yet.