description

The Introduction of the KGY industrial Heater Model KG140

The KGY industrial heater model KG140 provides heating, fresh air, and air recirculation for your greenhouse. With a solid body and an exclusive chassis system, the KG140 boasts durability and reliability. Equipped with an axial fan, it distributes warm air through a duct system or free blowing, making it suitable for both indoor and outdoor installation.

The body of the KGY industrial heater model KG140 is constructed from hot-galvanized material with furnace electrostatic powder paint, providing protective and optical resistance. An exhaust is utilized to remove combustion products, and for hard-to-reach areas, on-site assembly is possible.

With a thermal capacity of 250,000 kcal/h, the KG140 is available in two models, with and without a damper. Apart from greenhouse and poultry farm use, it is also suitable for sport halls, garages, warehouses, and more.

The Performance of the KG140

The KG140 Heater is a warm air furnace utilizing gasoil and gas as its fuel. It comes in two models: one with a damper for outdoor installation and one without for indoor use. In the damper model, cold air, after passing through the combustion chamber and thermal surfaces, is distributed to the hall interior by the axial fan. When the heater is turned off, the damper automatically closes, preventing the entry of cold air.

By installing KGY industrial heaters, air circulation in the hall is ensured, eliminating the need for an automatic damper and saving on operating expenses.

The Structure of the KG140

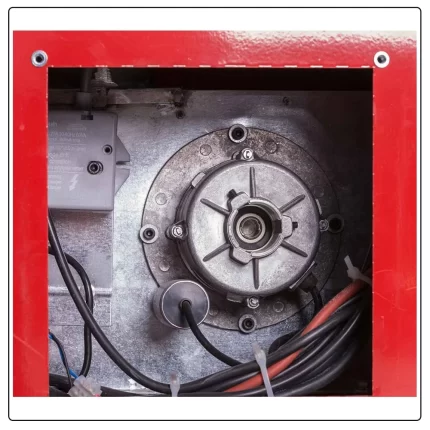

The KGY Industrial Heater Model KG140 greenhouse heater features a galvanized body coated with electrostatic powder paint for protective and optical resistance. Components include a multi-layer heat exchanger, pressed and detachable connections, axial fan, and automatic damper. The combustion chamber is made of stainless steel, and for ease of movement, this heater is equipped with a hook. Two models (with damper, without damper) are available for different applications.

The Control of KG140

The burner of this greenhouse heater can be turned off through control panels. The KG140 can be controlled using furnace and exhaust air temperature sensors. The electrical and mechanical panel includes various sensors ensuring correct operation and safety. By turning off the burner, the fan can be adjusted for continuous hall ventilation.

The KGY Industrial Heater Model KG140Additional Features:

– Phase Charge Control: Controls voltage level, phase order, and protects the electric motor.

– Miniature Fuse: Protects the heater from electric short circuits and current increases.

– Mode Choosing Switch: Enables independent fan operation for ventilation without heating.

– Mechanical Frame, Start/Stop: Initiates and controls single-phase and three-phase motors.

– 12A Contactor: Controls various charges, including electromotors and circuits.

– Glass Relay: Utilizes magnetism to connect and disconnect contacts.

– Analog Thermostat: Controls burner flame and fan operation.

– Propeller: Exclusive design for low noise and maximum pressure.

– Automatic Damper: Convenient and prevents heat loss and dust and insect entry.

– Automatic Centrifugal System: Opens and closes the damper automatically with fan activation.

– Electromotor: Three-phase motor design with optimal location and belt cooling.

The KGY Industrial Heater Model KG140 is a comprehensive solution for efficient and controlled heating in various environments.

Reviews

There are no reviews yet.