Description

Introduction to the WA Series Industrial Cabinet Heater:

The KGY WA series industrial heater is designed to provide heating, fresh air, and air recirculation for various environments. This solid cabinet heater features a quick assembly chassis system, making it a versatile solution. Equipped with a centrifugal fan, it can be connected to different ducts or operate without a duct. It can be installed both indoors and outdoors, with an exhaust system to eliminate combustion products. For hard-to-reach areas, on-site assembly is possible. The KGY WA series is available in three sizes, ranging from 150,000 to 450,000 kcal, ensuring flexibility for different applications. High safety, efficiency, and durability characterize this industrial heater, leading to cost savings in maintenance.

The Usage of the KGY WA Series Industrial Cabinet Heater:

Apart from industrial and production halls, the KGY WA series is suitable for applications in greenhouses, sports halls, garages, repair shops, workshops, printing offices, exhibitions, sales centers, wood industries, and chemical industries.

The Performance of the KGY WA Series Industrial Cabinet Heater:

- The KGY WA series cabinet heater operates on gasoil and gas.

- It is optimal for maintaining a constant temperature and ensuring uniform heat distribution.

- The new generation of the KGY WA series heaters offers a flexible, individually adaptable, and cost-effective solution for purchase, installation, and operation.

- WA series heaters can achieve a suitable temperature in large halls in less than 20 minutes, resulting in reduced operating expenses.

- Rapid heat distribution helps maintain a constant temperature in environments with frequent door openings.

- The cabinet heaters can be equipped with ducts for fresh air supply, reducing energy consumption.

- KGY service engineers can provide free measurements and calculations for individual heating demands.

- Installation of the KGY WA series industrial heater is quick and straightforward, requiring only electricity, gas/diesel connection, and chimney outlet.

- The control can be managed by a room thermostat or KGY program panel for air heating and recirculation.

- The KGY WA series heater is known for its longevity, featuring heat-resistant stainless steel combustion chambers and heat exchangers.

- Low maintenance costs are ensured, and KGY’s nationwide service network is available for customer support.

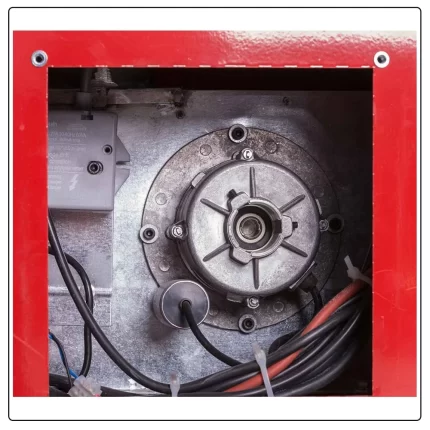

The KGY WA Series Cabinet Heater Control:

- The electrical panel, equipped with a mechanical control system, ensures high safety.

- Control through furnace and exhaust air temperature sensors is possible.

- Manual adjustment of the fan status is available for continuous ventilation.

- Clock programming allows setting specific on/off times.

- The burner can be manually turned off, and a soft starter or star triangle reduces electric motor shock current.

The KGY WA Series Cabinet Heater Components in the Electrical Panel:

25A Contactor: Used to control various loads, including electric motors.

Glass Relay: Utilized for electromagnetic separation or connection of contacts.

Signal Lights: LED indicators showing the presence of three-phase electricity.

Furnace Thermostat: High-temperature sensors connected to the digital temperature controller.

Phase Control: Used to control voltage level and phase order of input power.

Thermal Switch: Protects the electric motor from thermal current and electrical overload.

Miniature Three-Phase Fuse: Protects the cabinet heater from electric short circuits and current increases.

Performance Clock: Measures heater performance, calculates fuel usage, and determines service intervals.

Manual Emergency Switch: Allows for quick shutdown in case of danger or accidents.

Selection Mode Switch: Enables independent fan operation or automatic mode for burner and fan activation.

Reviews

There are no reviews yet.