In the poultry industry, proper heating is vital for chick health, growth, and production efficiency. Hot air furnaces are the most widely used heating systems for poultry houses, also known as broiler houses. These furnaces circulate warm air to maintain the desired ambient temperature throughout the house. This article explores the importance of poultry heating, delves into poultry hot air furnaces - their types, components, installation, and commissioning.

table of content

ToggleWhy Poultry Heating Matters:

- Maintaining Optimal Temperature: Chicks depend on heat to regulate their body temperature. In cold environments, they expend more feed to generate heat, leading to higher costs and lower feed conversion ratio (FCR).

- Disease Prevention: Low temperatures compromise the chicks' immune system, making them vulnerable to diseases like coccidiosis or Newcastle disease. Diseases can result in chick mortality, treatment expenses, and production losses.

- Ensuring Proper Growth: Proper temperature is essential for healthy chick development. Cold temperatures hinder growth and might lead to skeletal problems like leg deformities.

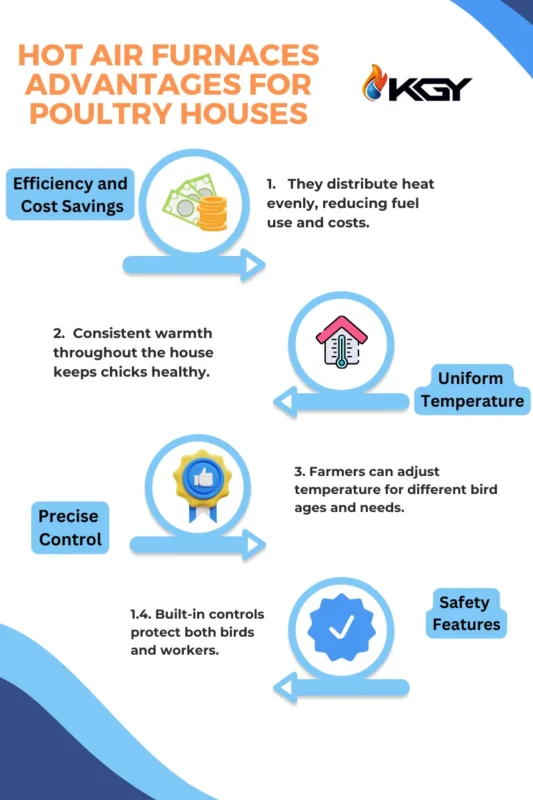

Advantages of Hot Air Furnaces for Poultry:

- High Efficiency: Poultry hot air furnaces employ powerful fans to distribute warm air evenly throughout the house. This ensures rapid heating and consistent temperature maintenance. Their high thermal efficiency optimizes fuel consumption and significantly reduces operational costs.

- Uniform Temperature Distribution: A key benefit of hot air furnaces is their ability to maintain consistent temperature throughout the poultry house. This eliminates cold and hot spots, providing ideal conditions for chick health and growth.

- Precise Temperature Control: Hot air furnaces come equipped with accurate thermostats for setting the desired temperature precisely. This allows poultry farmers to adjust the temperature based on chick age, weather conditions, and specific needs for broilers or layers.

- Enhanced Safety: Advanced control and safety features are built into hot air furnaces, ensuring the safety of both chicks and farm workers.

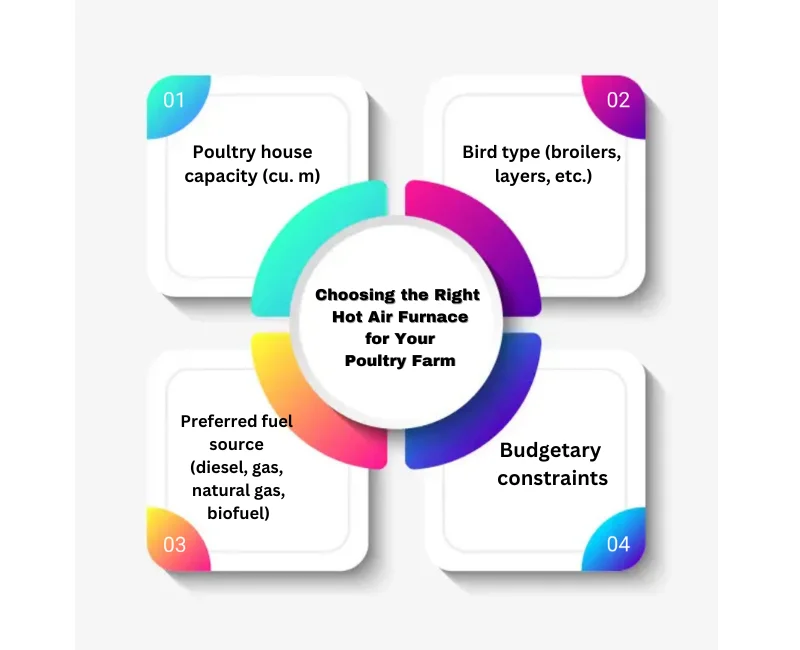

Choosing the Right Hot Air Furnace for Your Poultry Farm

- Type of Chicks: Different chicks require varying temperature ranges. For instance, broiler chicks typically need higher temperatures than layer chicks.

- Chick Age: Younger chicks require more warmth. As they mature, the temperature requirement gradually decreases.

- Poultry House Size: Larger poultry houses necessitate hot air furnaces with higher capacities (measured in BTU output) to ensure adequate heating throughout the house.

- Regional Climate: Colder regions require hot air furnaces with greater heating power to compensate for lower outside temperatures.

- Budget: Hot air furnaces come in various capacities and price ranges. Consider the initial investment alongside the long-term operational costs like fuel efficiency.

In sum, selecting the most suitable hot air furnace for your poultry farm is crucial for optimal chick health, growth, and production. By considering the factors mentioned above, you can make an informed decision and create the best possible environment for your chicks using a hot air furnace system.

Main Components of a Poultry Hot Air Furnace

Understanding the key components of a poultry hot air furnace is essential for informed maintenance and troubleshooting. Here's a breakdown of the essential parts:

- Burner: The heart of the furnace, the burner generates heat by combusting various fuel sources like propane, natural gas, or even biofuels (depending on the model) in a combustion chamber.

- How the Burner Works: Fuel and air mix precisely within the burner, igniting to create a flame. This flame's heat then transfers to the heat exchanger, preparing the hot air for circulation throughout the poultry house, also known as the broiler house.

- Heat Exchanger: This critical component acts as a heat transfer interface between the flame and the air. Made from a high-durability, heat-resistant metal like stainless steel, the heat exchanger absorbs heat from the flame and warms the air flowing through it. Heat exchanger efficiency plays a significant role in the overall thermal efficiency of the furnace.

- Blower Fan: Responsible for distributing the warmed air throughout the poultry house, blower fans come in various capacities to match the BTU output of the furnace and the size of the broiler house.

- How the Blower Fan Works: The blower fan pulls in cool air from the house and directs it over the heated heat exchanger. This warmed air is then forced out through a duct system for even distribution throughout the poultry house. Proper air circulation is vital for maintaining consistent ambient temperature and preventing cold spots.

Types of Poultry Hot Air Furnaces by Flame Type

- Direct Flame Hot Air Furnace: In this design, the flame burns directly within the combustion chamber, transferring heat straight into the poultry house environment. While offering high efficiency, precise temperature control can be more challenging with direct flame furnaces due to the radiant heat produced.

- Indirect Flame Hot Air Furnace: Here, the flame is contained in a separate chamber. The heat generated then reaches the poultry house environment indirectly through a heat exchanger. This design allows for more precise temperature control through a thermostat and offers enhanced safety compared to direct flame models by preventing combustion gases from mixing with the circulated air.

Factors Affecting Poultry Hot Air Furnace Performance

Several factors influence the performance and efficiency of your poultry hot air furnace, impacting your flock's health and farm profitability. Here's a breakdown of the key considerations:

1. Environmental Factors:

- Temperature: Ambient temperature significantly impacts the furnace's operation. Colder environments require the furnace to work harder to maintain desired broiler house temperature, leading to higher fuel consumption and reduced thermal efficiency.

- Humidity: High humidity levels can disrupt performance and cause rust or corrosion to furnace components. Proper ventilation in the poultry house is crucial for reducing humidity and preventing issues.

- Ventilation: Adequate ventilation is essential for supplying fresh air, removing moisture, and preventing harmful gas buildup like ammonia. Poor ventilation can hinder the hot air furnace's performance, endanger chick health, and contribute to respiratory problems.

2. Optimal Placement for Poultry Hot Air Furnace Installation:

- Even Heat Distribution: The furnace location should ensure even hot air distribution throughout the poultry house. Strategic placement can minimize temperature gradients and create a uniform environment for optimal chick comfort.

- Safety Considerations: Maintain a safe distance between the furnace and combustible materials like walls, bedding, and other equipment to prevent fire hazards. Following recommended installation clearances is essential.

- Accessibility for Maintenance: Easy access to the furnace is vital for routine servicing, maintenance, and repairs. Proper clearance around the furnace allows for technicians to perform necessary checks and ensure the unit operates safely and efficiently

- Temperature Control and Settings for Poultry Hot Air Furnaces:

- Age-Specific Temperatures: Setting the appropriate temperature for the chicks' age is crucial. Chicks have different brooder temperature requirements throughout their growth cycle. Providing the correct temperature range promotes chick health and growth.

- Precise Thermostats: Utilize a reliable and accurate thermostat to control the furnace and maintain the desired temperature within the poultry house. Consistent temperature control optimizes chick comfort and feed conversion ratio.

- Optimizing Fuel Consumption: Correct temperature settings and routine maintenance can optimize fuel consumption and increase the furnace's overall efficiency. This translates to lower operating costs and improved farm profitability.

By considering these factors and implementing best practices, you can ensure your poultry hot air furnace operates at peak performance, promoting optimal chick health, maximizing production efficiency, and achieving better flock performance.

Technical Specifications of Poultry Hot Air Furnaces:

Understanding the technical specifications of poultry hot air furnaces is crucial for selecting the most suitable unit for your farm's needs and maximizing flock performance. Here's a breakdown of key features to consider:

- Capacity (cu. m): Measured in cubic meters (cu. m), the capacity determines the furnace's ability to heat a specific broiler house volume. It directly correlates with the BTU output of the furnace. Capacity typically ranges from 5,000 cu. m to 50,000 cu. m, accommodating various poultry house sizes and chick populations.

- Fuel Type: Poultry hot air furnaces come in various fuel options, including liquefied petroleum gas (LPG), natural gas, diesel, and even biofuel models for a more sustainable approach. The most suitable fuel choice depends on factors like availability, cost, and efficiency.

- Thermal Efficiency: Modern hot air furnaces boast impressive thermal efficiency ratings, reaching up to 94% in some models. High efficiency translates to significant operational cost savings on your fuel consumption.

- Control System: Precise temperature control is crucial for chick health and feed conversion ratio (FCR). Poultry hot air furnaces come equipped with user-friendly control systems, often featuring digital thermostats for setting and maintaining desired temperatures with greater accuracy.

- Safety Systems: Safety is paramount in any poultry operation. Hot air furnaces incorporate features like automatic shut-off systems, high-temperature limit controls, and flame safeguards to ensure the well-being of both chicks and farm workers.

- Dimensions & Weight: As expected, dimensions and weight vary based on the furnace's capacity and BTU output. Consult with a reputable poultry equipment supplier to determine the most suitable size and weight for your house, considering factors like installation space and floor support.

- Price: The price of a poultry hot air furnace is influenced by factors like capacity, fuel type, brand reputation, and additional features like advanced control systems or multi-stage burners. Consider your needs, budget, and desired level of automation when making your selection.

In sum, Poultry hot air furnaces offer a multitude of advantages, making them an ideal heating solution for poultry houses. By providing consistent warmth, proper humidity control, and optimal ventilation, these systems play a vital role in promoting chick health, growth, and ultimately, farm profitability through efficient flock management.

Koolak Gostar Yazd: Your Trusted Partner for High-Efficiency Poultry House Heating

Koolak Gostar Yazd is your one-stop shop for premium poultry house heating solutions. We offer a diverse range of high-efficiency and affordable poultry hot air furnaces, ensuring optimal climate control for your birds throughout the year. Whether you're managing a small broiler operation or a large-scale layer farm, we have the ideal heating system to meet your needs.

Why Choose Koolak Gostar Yazd Poultry Hot Air Furnaces?

- Unmatched Selection: We provide a variety of poultry hot air furnaces to perfectly match your farm's requirements. From the high-output Super Jet Heater 300,000 to the economical ECO250 Heater, our selection includes the WA Series Heaters and the Jet Heater 100,000, ensuring you find the ideal broiler house heater for your specific flock size and desired BTU output.

- Unbeatable Efficiency: Our hot air furnaces boast an impressive efficiency rating of up to 94%, translating to significant savings on fuel consumption and operational costs. This translates to a faster return on investment and improved farm profitability.

- Clean & Odorless Operation: Koolak Gostar Yazd hot air furnaces guarantee complete fuel combustion, eliminating odor and harmful gas emissions. This protects the health of your chickens and creates a more pleasant working environment for farm personnel.

- Uncompromising Safety: Safety is our top priority. Our hot air furnaces are equipped with multiple control sensors, automatic shut-off systems, and high-temperature limit controls to prevent accidents and ensure a secure environment for your flock and your workers.

- Reliable Warranty & After-Sales Support: We stand behind our products. Koolak Gostar Yazd offers a comprehensive warranty and after-sales service program for your peace of mind. Our team of poultry heating specialists is readily available to answer your questions and address any concerns you may have.

Check our products for poultry

Poultry Hot Air Furnace FAQs:

A poultry hot air furnace is a heating system specifically designed to maintain optimal temperatures within poultry houses. It utilizes various fuel sources, such as diesel, gas, or even electricity, to generate hot air that's evenly distributed throughout the house. This consistent warmth is crucial for chick health, growth, and overall flock performance.

- Requires dedicated installation space within the poultry house.

- Carries a higher initial investment cost compared to some brooding heating systems.

- Regular maintenance and repairs are necessary for optimal performance and safety.

By choosing Koolak Gostar Yazd poultry hot air furnaces, you're investing in a reliable, efficient, and safe heating solution for your poultry farm. Contact us today to discuss your specific requirements and find the perfect hot air furnace to optimize your flock's health and production!