Description

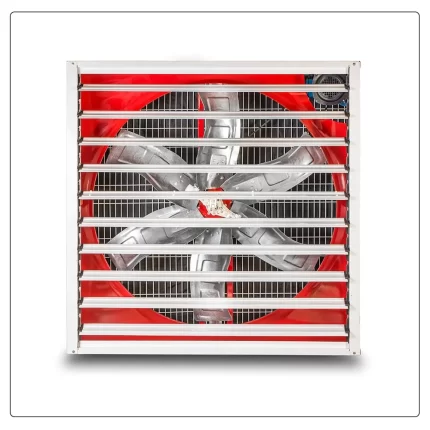

The KGY Exhaust Fan Introduction:

The KGY industrial ventilators represent an advanced generation of fans, meticulously redesigned to minimize energy consumption, enhance efficiency, and reduce maintenance costs. Available in three sizes (100, 120, and 140), these ventilators are specifically engineered for optimal ventilation in industrial environments, poultry farms, and greenhouses.

The KGY Exhaust Fan Structure and Advantages:

The power transmission section incorporates robust components such as high-strength shafts, pulleys, and bearings. This, coupled with a precise design, ensures the KGY ventilator’s durability and quality.

The body is constructed with hot-galvanized material, featuring a high thickness and a double chassis that significantly reinforces its strength.

Aerodynamic blades, housed in a specially designed metal casing, amplify the air output of the fan.

Hinged mesh doors provide quick access to internal parts, facilitating both protection and maintenance procedures.

The KGY exhaust fan is equipped with a centrifugal damper and belt tensioner, contributing to its efficient operation.

Designed with specific handles, the ventilator is easily transportable.

KGY exhaust fans carries four international standard marks and holds European Union CE certification, attesting to its compliance with quality and safety standards.

The KGY Exhaust Fan Control:

KGY industrial ventilators can be seamlessly integrated with electrical and automation control panels. This integration allows for the adjustment of pressure, temperature, and the balancing of different gases within the facility.

In summary, the KGY industrial ventilators boast a robust structural design, incorporating advanced features that not only ensure durability and efficiency but also facilitate ease of control and maintenance. The ventilators are positioned as a reliable solution for diverse industrial, agricultural, and greenhouse applications.

Reviews

There are no reviews yet.