Have you ever wondered what makes evaporative coolers a standout choice for industrial cooling? Are you seeking an energy-efficient and cost-effective solution for your large spaces? If so, this KGY blog post is for you.

Industrial evaporative coolers, also known as swamp coolers, offer a natural and efficient way to reduce air temperature, especially in dry, hot climates. Unlike traditional air conditioners that rely on refrigerants and compressors, these coolers utilize the simple process of evaporation to provide a refreshing environment.

In this article from the KGY website, we explore the advantages of industrial evaporative coolers over traditional HVAC systems. Learn why evaporative coolers are revolutionizing industrial climate control and why they are a smart choice for manufacturing. Dive into their benefits, maintenance tips, and effective cooling performance. Keep reading to find out how industrial evaporative coolers can transform your workspace.

Table of Contents

ToggleHow an industrial evaporative cooler works?

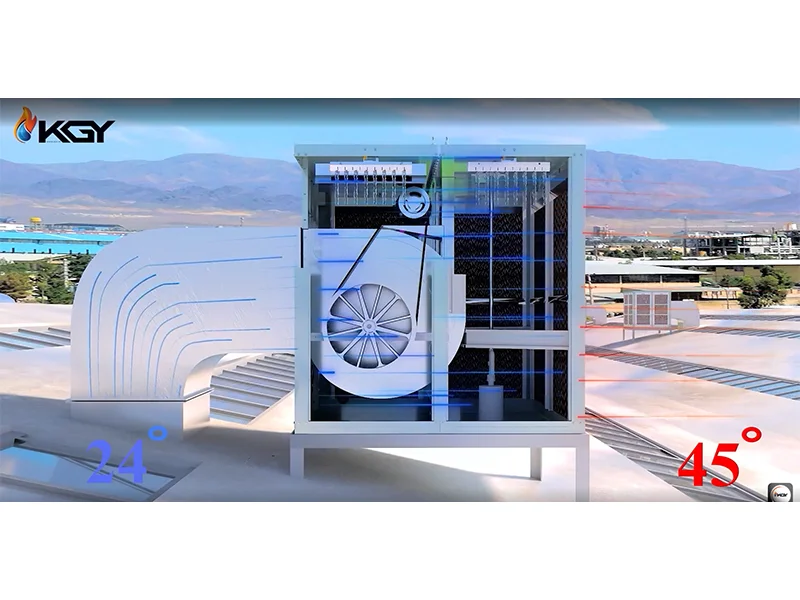

Evaporative cooling works by drawing warm air through water-soaked cooling pads. As the air passes through these pads, the water evaporates, absorbing heat and reducing the air temperature. This cool air is then circulated throughout your industrial space, creating a comfortable and refreshing environment. The process not only cools the air but also increases humidity, which can be beneficial in arid regions.

The Importance of Cooling in Manufacturing

Extreme heat can significantly impact industrial production. Workers become less productive in sweltering conditions, with potential safety risks like heatstroke. Manufacturing processes themselves can be affected – certain materials react poorly to heat, and machinery can malfunction. Disruptions like power outages due to increased energy demands can further damage production. These factors combine to slow down assembly lines and decrease overall output. To counter this, industries are exploring heat mitigation strategies like industrial evaporative coolers and adjusting work schedules. Industrial evaporative coolers not only enhance worker comfort and productivity but also protect equipment and maintain product quality, making them a vital component in any manufacturing operation.

Air conditioning VS evaporative cooling

Air conditioners use electricity to cool air by removing heat, making them effective in all climates but costly to operate. Industrial evaporative coolers, or swamp coolers, work by passing hot air over water-soaked pads, releasing cooler, moister air. Industrial evaporative coolers are energy-efficient and perfect for hot, dry climates but less effective in humid areas.

Unlike complex air conditioners with numerous parts, industrial evaporative coolers have a surprisingly simple design. The core components of an industrial evaporative cooler consist of a pump, fan, and water pads. This translates to lower maintenance costs and fewer potential breakdowns.

The pump circulates water over the pads, while the fan pulls in hot air. As the water evaporates, it cools the air significantly. This straightforward design minimizes energy consumption, keeping your running costs cool alongside your workspace. So, if you're looking for a reliable and cost-effective cooling solution for your industrial environment, consider the simple elegance of evaporative coolers.

Read More: Greenhouse Pad Cooling Systems

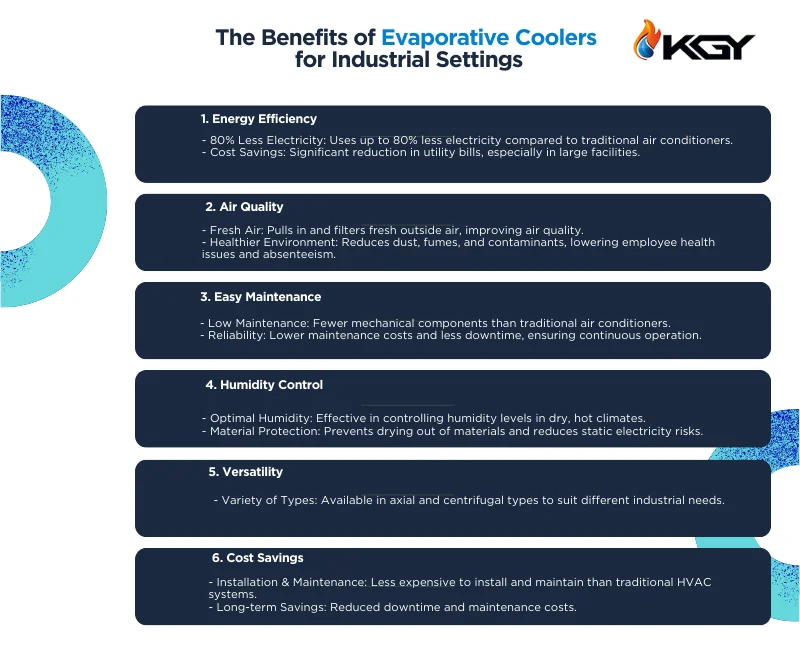

The Benefits of Evaporative Coolers

Industrial evaporative coolers offer numerous benefits for industrial settings, making them a popular choice for many businesses. These cooling systems are particularly advantageous in large spaces such as warehouses, factories, and manufacturing plants where maintaining a comfortable environment is crucial for both productivity and equipment longevity.

Energy Efficiency

Evaporative cooling is revolutionizing climate control. Unlike traditional air conditioners, evaporative coolers use up to 80% less electricity. it cools significantly using minimal energy, and unlike AC, it doesn't just recirculate stale air. This can lead to substantial cost savings on utility bills, especially in large facilities that require extensive cooling.

Air Quality

Another key advantage is the improved air quality that evaporative coolers provide. Unlike conventional air conditioners that recirculate the same air, industrial evaporative coolers pull fresh air from outside, filter it, and then cool it through the evaporation process. This constant influx of fresh air helps to remove dust, fumes, and other airborne contaminants, creating a healthier working environment. Improved air quality can reduce employee health issues and decrease absenteeism, thereby enhancing overall productivity.

Easy Maintenance

Industrial evaporative coolers are also relatively easy to install and maintain. Industrial evaporative coolers have fewer mechanical components than traditional air conditioners, resulting in lower maintenance costs and less downtime. In industrial settings, where continuous operation is often necessary, the reliability and ease of maintenance of industrial evaporative coolers are significant advantages.

Humidity Control

Additionally, the industrial evaporative coolers are effective in controlling humidity levels, which is beneficial in dry, hot climates. Maintaining optimal humidity levels can prevent the drying out of materials and reduce the risk of static electricity, which can damage sensitive equipment.

Versatility

Industrial evaporative coolers come in various types to suit different needs. The two most common type of industrial evaporative coolers are Axial evaporative coolers and centrifugal evaporative coolers. This versatility allows you to choose the most effective cooling solution for your unique industrial setting.

Cost Savings

Beyond energy efficiency, industrial evaporative coolers are typically less expensive to install and maintain than traditional HVAC systems. Their lower maintenance requirements and fewer mechanical parts mean reduced downtime and long-term savings.

Equipment Protection

Excessive heat can damage manufacturing equipment, causing costly downtime and repairs. Industrial evaporative coolers help dissipate heat, ensuring machinery operates within safe temperature ranges and extending the lifespan of equipment

Cons of Evaporative Coolers

- Limited Cooling in Humid Conditions: Industrial evaporative coolers are less effective in extremely humid conditions because they rely on the evaporation of water to cool the air. They work best in hot, dry climates.

- Humidity Increase: While beneficial in dry climates, the added humidity can be a disadvantage in areas that are already humid, potentially leading to discomfort or mold growth.

What Should Be Considered When Choosing an Industrial Cooler

Selecting the right industrial evaporative cooler is crucial for maintaining an efficient and comfortable manufacturing environment. Here are key factors to consider:

- Climate Compatibility: Consider the climate where the cooler will be used. Industrial evaporative coolers are highly effective in hot, dry climates but may be less efficient in humid areas. For humid environments, traditional HVAC systems might be more suitable.

- Cooling Capacity: Assess the size of the area that needs cooling. Industrial evaporative coolers or swamp coolers come in various capacities, so choose one that can effectively cover your entire space. Overestimating capacity can lead to energy waste, while underestimating can result in insufficient cooling.

- Energy Efficiency: Look for energy-efficient models to reduce operational costs and minimize environmental impact. Energy-efficient coolers like industriual evaporative coolers use less electricity, which can significantly lower your energy bills.

- Maintenance Requirements: Consider the maintenance needs of the industrial cooler. Choose a system with easy-to-replace parts and straightforward cleaning procedures to minimize downtime and maintenance costs.

- Air Quality: Evaluate the air quality benefits of the industrial cooler. Evaporative coolers improve air quality by bringing in fresh air and filtering out dust and contaminants, which can be beneficial in industrial settings.

By considering these factors, an industrial evaporative cooler by ensuring efficient cooling, enhanced productivity, and cost savings is the best choice.

Maintenance Tips of Industrial Evaporative Coolers

- Regular Cleaning: Clean the water tank and pads regularly to prevent mineral buildup and mold. This keeps the air fresh and the system efficient.

- Pad Replacement: Check the cooling pads for wear and replace them as needed. Worn pads reduce the cooler’s efficiency.

- Water Level: Maintain the proper water level. Too little water can reduce cooling efficiency, while too much can cause overflow.

- Seasonal Maintenance: At the start and end of the cooling season, perform a thorough inspection and cleaning. Drain the water and clean all components to prevent damage and ensure readiness for the next season.

By following these installation and maintenance guidelines, you can ensure your Industrial evaporative cooler runs efficiently, providing effective and economical cooling for your space.

Conclusion:

In this blog post from the KGY website we highlighted how evaporative cooling is revolutionizing climate control by providing an energy-efficient and eco-friendly alternative to traditional air conditioning. Evaporative coolers offer a multitude of benefits for industrial settings, including unparalleled energy efficiency, improved air quality, ease of maintenance, and effective humidity control. As the demand for sustainable solutions grows, evaporative cooling is becoming increasingly popular in industrial environments, supporting both cost savings and environmental goals.

Why choose KGY?

KGY industrial evaporative coolers are held in high regard in the air cooler market. Our team of professionals have decades of expertise in air units for industry and businesses. We understand the nuances needed for different applications and place this knowledge directly in our customers' hands, ensuring they get the solution that’s most effective for what they need.

The KGY industrial evaporative coolers let you eliminate fumes and odors, obtain new, fresh, filtered air, and have constant ventilation in your warehouse, plant or company.

Our experience developing ecological and healthy innovations for energy use has enabled us to become leaders in our field. We bring the highest spec technology that’s driven by protecting the environment.

To find out more about what evaporative cooling can do for you, explore our full product range.

Frequently Asked Questions About Using Industrial Evaporative Coolers

Evaporative coolers are highly effective in large, open spaces like warehouses and factories, especially in hot, dry climates. They provide substantial cooling at a fraction of the energy cost of traditional HVAC systems.

Evaporative coolers work best in dry climates. In humid environments, their efficiency decreases as the air cannot absorb as much moisture, resulting in less effective cooling.

Maintenance is straightforward and includes regular cleaning of the water tank and pads, checking and replacing pads as necessary, and ensuring a consistent water supply. Periodic inspections and seasonal maintenance help keep the industrial evaporative cooler running efficiently.

Evaporative coolers improve indoor air quality by drawing in fresh air from outside, filtering it through water-soaked pads, and reducing dust and contaminants. This can create a healthier working environment compared to traditional HVAC systems that recirculate indoor air.

Yes, evaporative coolers are cost-effective. They have lower initial purchase and installation costs compared to HVAC systems. Additionally, they consume less electricity, leading to lower operational costs and energy savings.

Evaporative coolers are designed for continuous operation, which is ideal for industrial settings. Regular maintenance ensures they run efficiently without frequent breakdowns.